Gasketed Plate Heat Exchanger Brazed Plate Heat Exchanger Welded Plate Heat Exchanger Plate and Shell Heat Exchanger Plate Evaporator Plate Condenser |

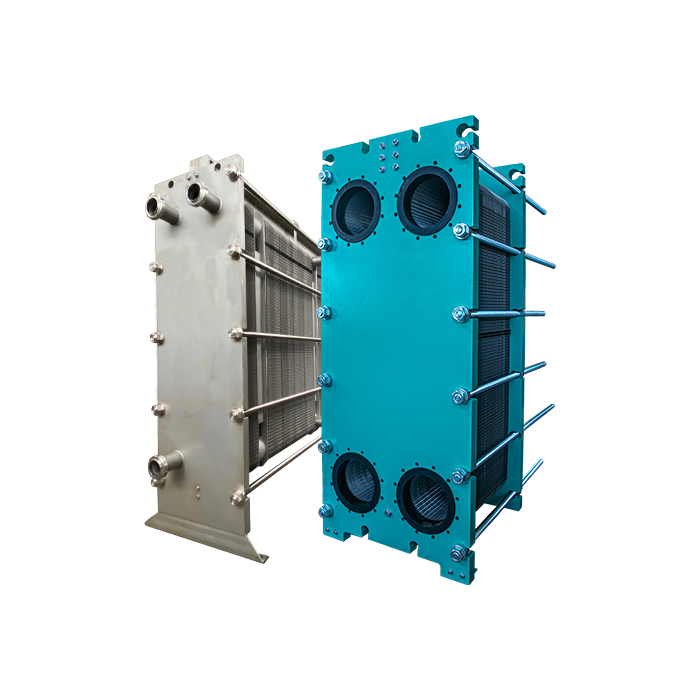

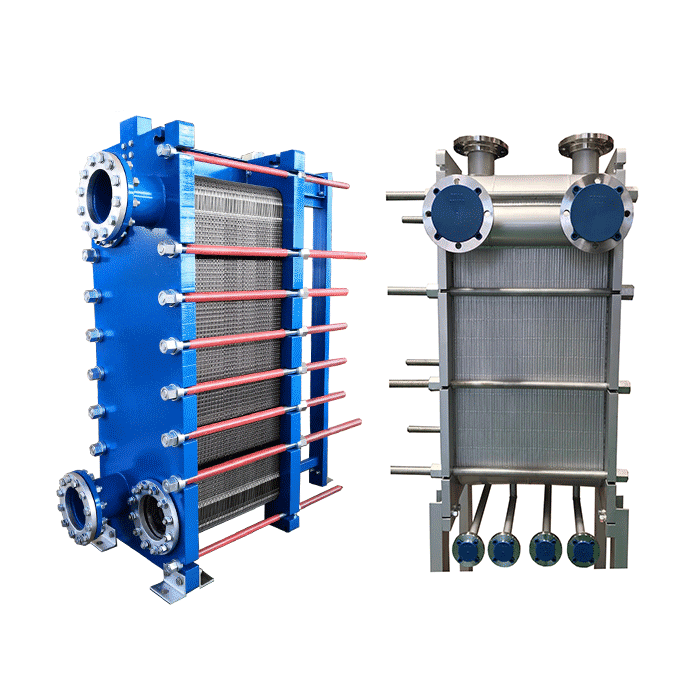

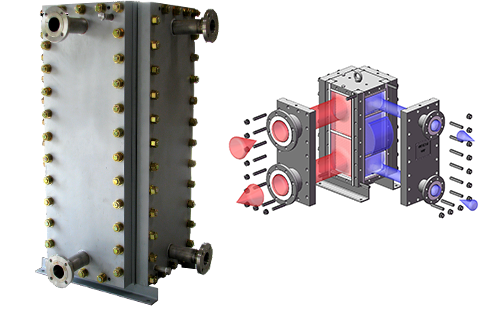

Gasketed Type Plate Heat Exchanger

Brazed Plate Heat Exchanger

Welded Plate Heat Exchanger

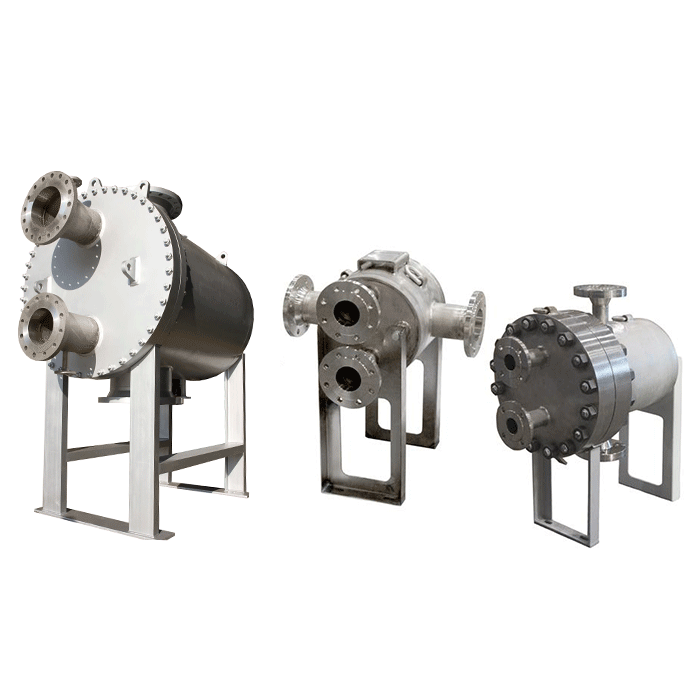

Plate& Shell Heat Exchange

PHE Application Design

Greenleading designs and supplies standard and customized plate heat exchangers. The optimized and high efficient PHE solutions and good quality products are trusted by more and more clients from various industries for their heating and cooling processes.

PHE Service Know-how

Greenleading service team together with our global service partners to share the professional service experience across the world including on-site assemble and disassemble, installation, cleaning, regasketing, leakage &pressure test, and refurbishment.

Plate Heat Exchangers

supplies gasketed plate heat exchanger (plate and frame heat exchanger), brazed plate heat exchanger (filler copper /nickel /stainless steel), welded plate heat exchanger (semi-welded PHE, all welded PHE, plate and shell heat exchanger), and PHE condenser and evaporator.

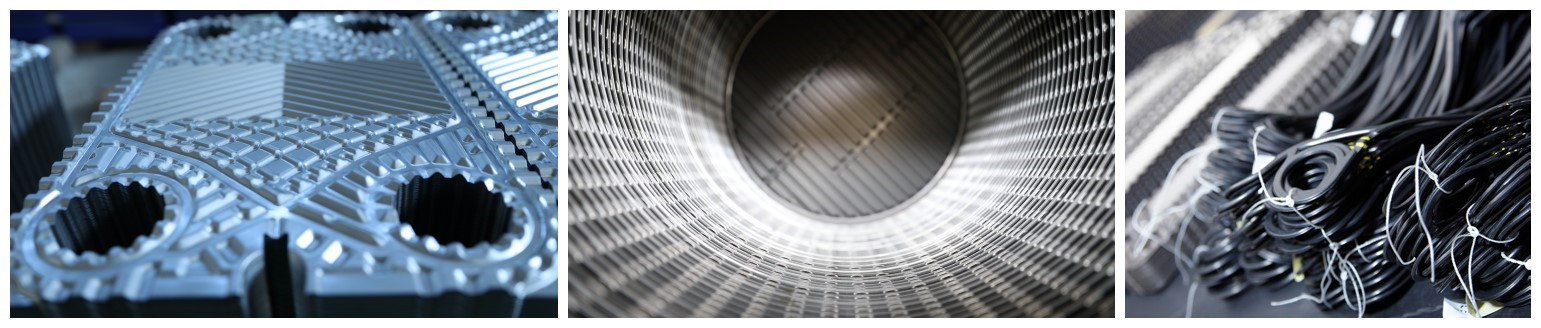

Gaskets & Plates

GL provides high quality plates and gaskets multi-brands non-OEM replacement.The high quality raw material gaskets (EPDM, NBR & VITON) and plates (stainless steel, titanium, hastelloy) replacement for GEA, APV, Tranter, Sondex, Hisaka, Vicarb, Sigma, Mueller etc.

Greenleading plate heat exchangers are applied in industrial sections:

Power and Energy, Oil and Gas, Petrochemical, Marine, Food and Beverage, Paper and Pulp, Chemical, Steel Production, HVAC, Waste Water Treatment, Mining, Construction HVAC, etc.

Greenleading supplies various types of plate heat exchanger for industrial heating and cooling duties

Design Temperatures: -196℃ ~ 550℃

Brazed Plate Heat Exchanger

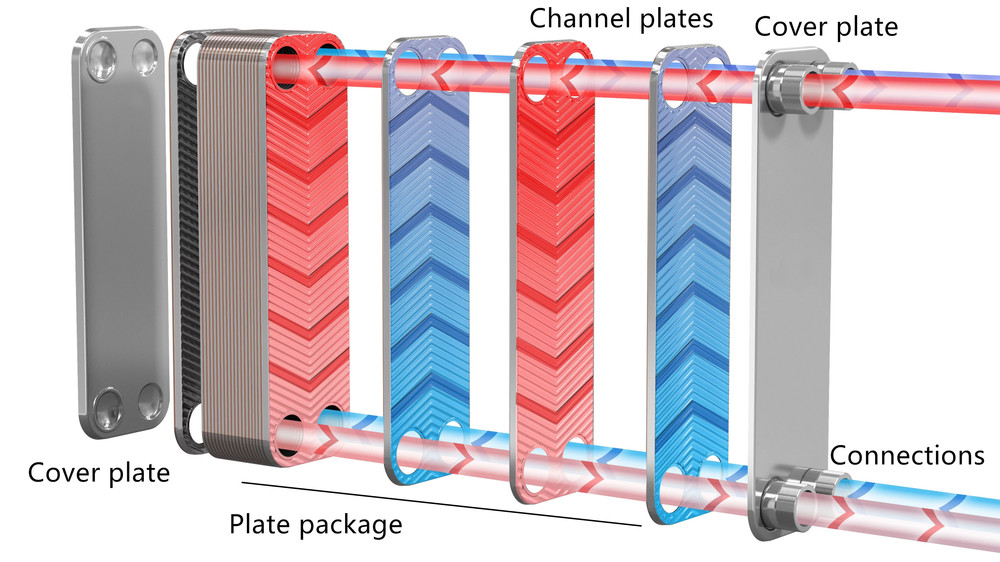

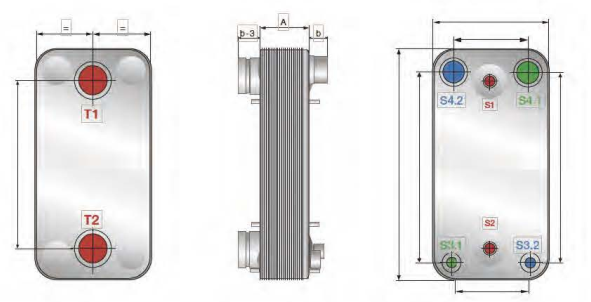

A Brazed Plate Heat Exchanger is a small, light and compact type of plate heat exchanger. It does not need gaskets. Instead, the plate pack is brazed together using cooper or nickel to give a strong and compact construction. The plate pack is a brazed frame made of metal plates in stainless steel, ss304 or ss316.

What are the advantages of Brazed Plate Heat Exchanger?

High heat transfer efficiency

Compact structure

Easy installation

Easy Deinstallation

Durability

Table. Parameters of GL Brazed Plate Heat Exchanger:

| Model No | Width | Highth | Thickness | Hole Center Distance | Max Pressure | Max Flow Rate | Weight |

| HQ10 | 76 | 206 | 9+2.3n | 172*42 | 1/3/4.5 | 8.0 | 0.7+0.06n |

| HQ15 | 80 | 190 | 9+2.3n | 154*40 | 1/3/4.5 | 8.0 | 0.7+0.06n |

| HQ25A | 78 | 318 | 9+2.3n | 282*42 | 3/4.5 | 8.0 | 1.0+0.08n |

| HQ25B | 86 | 315 | 9+2.3n | 269*40 | 3/4.5 | 8.0 | 1.0+0.08n |

| HQ30 | 111 | 310 | 10+2.36n | 250*50 | 3/4.5 | 18 | 1.3+0.12n |

| HQ35 | 124 | 304 | 13+2.4n | 250*70 | 3/4.5 | 18 | 2.2+0.16n |

| HQ36 | 122 | 282 | 11+3.1n | 227*52 | 3 | 18 | 1.88+0.104n |

| HQ52A | 111 | 525 | 10+2.35n | 466*50 | 3/4.5 | 18 | 2.6+0.19n |

| HQ52B | 111 | 525 | 10+2.35n | 466*50 | 3/4.5 | 18 | 2.6+0.21n |

| HQ60A | 119 | 526 | 10+2.24n | 470*63 | 3/4.5 | 18 | 2.379+0.194n |

| HQ60B | 119 | 526 | 10+2.24n | 470*63 | 3/4.5 | 18 | 2.379+0.194n |

| HQ90A | 191 | 616 | 11+2.35n | 519*92 | 3/4.5 | 42 | 7.8+0.36n |

| HQ90B | 191 | 616 | 11+2.72n | 519*92 | 3/4.5 | 42 | 7.8+0.44n |

| HQ100 | 248 | 496 | 10+2.15n | 405*157 | 3/4.5 | 42 | 6.5+0.37n |

| HQ125A | 246 | 528 | 13+2.36n | 456*174 | 3/4.5 | 42 | 7.2+0.52n |

| HQ125B | 246 | 528 | 13+2.36n | 456*174 | 3/4.5 | 42 | 7.2+0.52n |

| HQ180 | 307 | 696 | 13+2.76n | 567*307 | 1.5/2.1 | 100 | 10+0.51n |

| HQ210 | 321 | 738 | 13+2.7n | 603*188 | 1.5/2.1 | 100 | 13+0.75n |

| HQ210A | 321 | 738 | 13+2.7n | 603*188 | 1.5/2.1 | 100 | 13+0.75n |

| HQ230 | 322 | 739 | 13+2.55n | 631.7*205.2 | 3/4.5 | 100 | 13+0.82n |

| HQ600 | 429 | 1398 | 22+2.78n | 1190*220 | 1.5/2.1 | 300 | 31.8+1.73n |

Welded Plate Heat Exchanger

Welded Plate Heat Exchanger

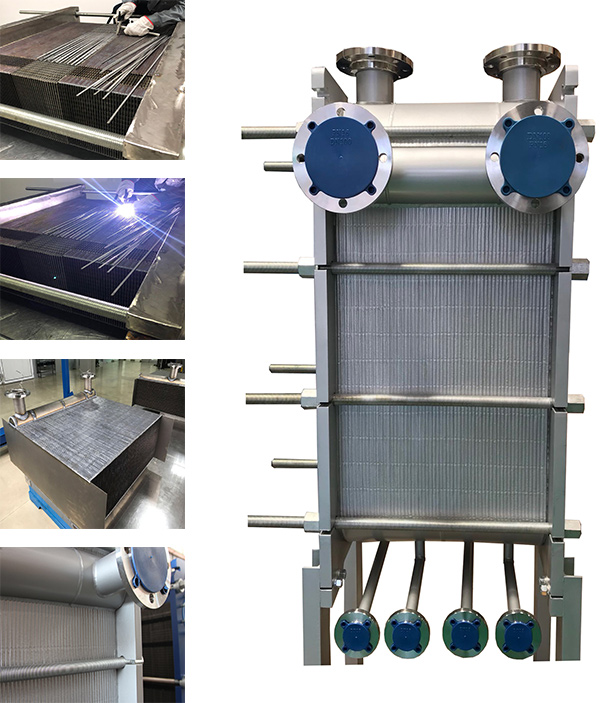

All-welded plate heat exchanger is a kind of plate type heat exchangers that can endure high temperature and high pressure. Highest temperature 400°C, pressure 3.5Mpa. Relying on application practices, Fully welded plate heat exchangers are applied in oil and gas industry, refinery applications, pharmaceutical industry, chemical/petrochemical industry.

Compared with tubular heat exchanger and gasketed plate type heat exchanger, weleded plate heat exchanger has the advantages:

Small size and compact structure

Light weight

High efficiency and low heat loss

Less cost and free gasket maintenance

Plate pattern: Herringbone

Bloc Heat Exchanger

It is a compact solution to work in high operating pressures, and high or low operating temperatures. HFM can make the replacement of the Alfa Laval compact bloc heat exchanger.

Advantages:

• fully welded by robot

It is available in several models, ranging from 2.4 sqm, up to 1,530 sqm of heat transfer area. Design Pressure: Vacuum / 50 barg. Design Temperature: - 40 °C / 400 ºC.

Available Materials:

• SS316L (Standard)

• Titanium & Titanium + 0.2 Pd.

• Hastelloy® C-2000, C-276, C-22, B2

• Avesta 254 SMO, 904L

• Nickel

Semi-welded Plate Heat Exchanger

What are the advantages of Semi-Welded Plate Heat Exchanger?

1. Wide temperature range from -38℃ to 200℃

2. Maximum design pressure up to 30 bar

3. Rigid mechanical construction

4. Outstanding leakproofness for high safety

5. Capacity in handling aggressive media

6. Adjustable size, compact structure, small space

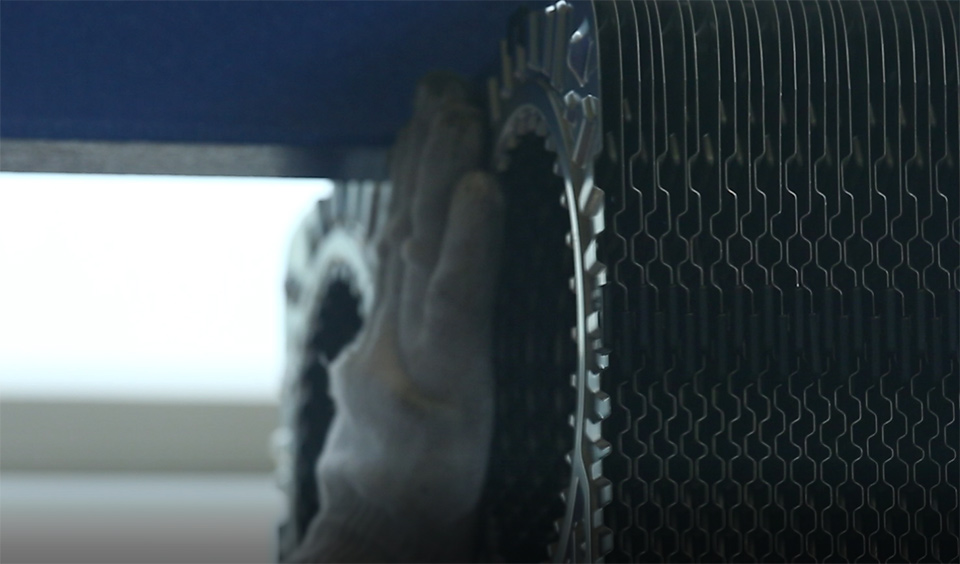

The Semi-welded Plate Heat Exchanger is particularly offered for heating and cooling of aggressive media. Two corrugated plates are positioned back to back and welded together as "cassette" by laser, along the sealing groove designed for the gasket of the semi welded PHE.

The semi-welded plate for PHE is specially offered for aggressive media. Generally, two pieces of PHE stainless steel plates are welded back to back by laser along the sealing groove for the gasket to form the plate cassette. Each cassette is sealed with a gasket. The refrigerant flows from one cassette to the other, contacting with only two of the four ring gaskets at the inlet and the outlet.

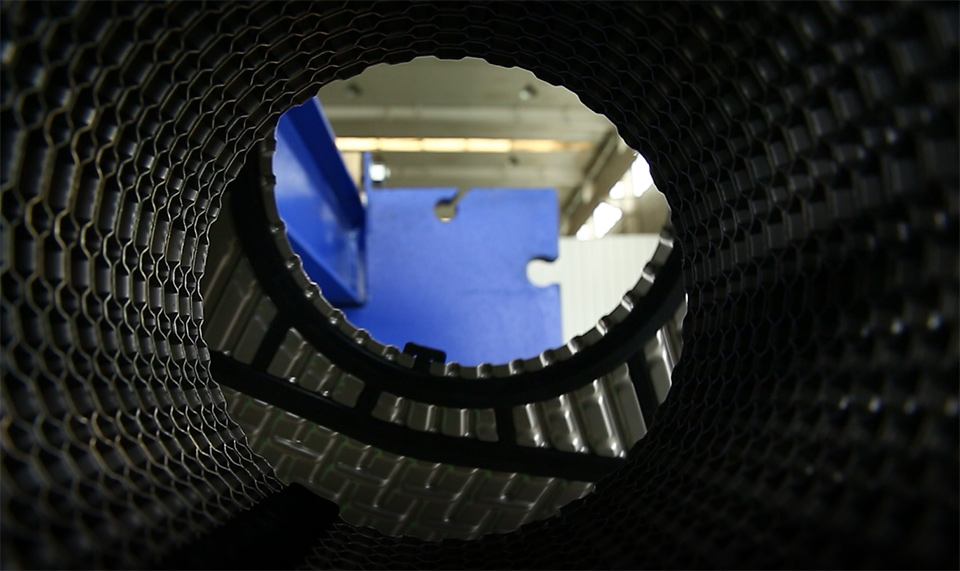

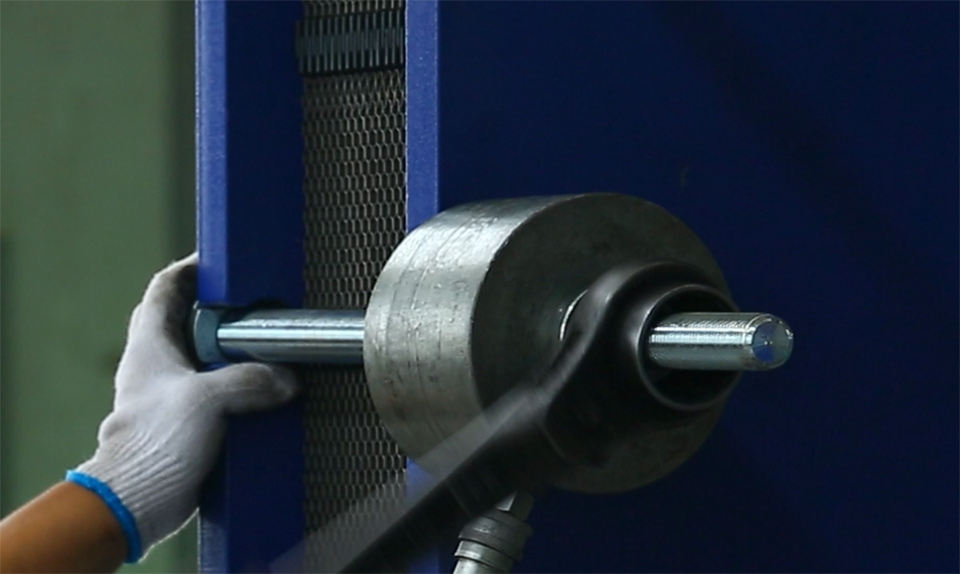

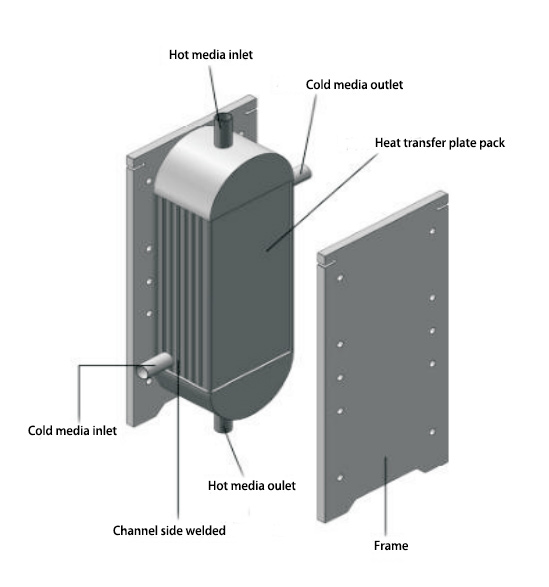

Plate and Shell Heat Exchanger

Plate and Shell Heat Exchanger is designed as a performance upgrade over shell & tube heat exchanger and welded, brazed plate heat exchangers. This heat exchanger type supplies high thermal performance with compact size, similar to that ofgasketed plate heat exchangers, with low hold-up volume and low installed weight, especially when filled. But it can be applied well when the operation condition is high temp and high pressure to which gasketed plate heat exchangers cannot be applied.

The heart of the Plate and Shell Heat Exchanger is its heat transfer element, also called the plate core/package, composed of round or oblong chevron-type plates welded into a cassette.

What are the advantages of Plate and Shell Heat Exchanger?

High heat transfer & Low fouling

Compact structure & No gasket

High pressure & High temperature

Small terminal temperature difference & Low pressure drop

Table. Parameters of GL Plate and Shell Heat Exchangers

| W | W1 | D | D1 | L | Plate+Tube | Shell+Tube |

| 240 | 98 | 250 | 168.3 | N*2.4+2 | DN15 | DN(15-80) |

| 448 | 134.6 | 310 | 219.1 | N*2.4+3 | DN20 | DN(20-100) |

| 469 | 174 | 368 | 269 | N*2.4+4 | DN40 | DN(25-200) |

| 565 | 277 | 460 | 355 | N*2.8+4 | DN50 | DN(25-300) |

| 600 | 298 | 694 | 464 | N*2.8+6 | DN80 | DN(25-350) |

| 693 | 338 | 725 | 559 | N*2.8+6 | DN100 | DN(25-400) |

| 1520 | 650 | 1250 | 1016 | N*3.2+6 | DN150 | DN(25-700) |

| 1828 | 900 | 1548 | 1372 | N*3.2+8 | DN300 | DN(25-1000) |

| 2098 | 1000 | 1838 | 1562 | N*3.2+8 | DN350 | DN(25-1200) |

Plate Evaporator

Recommended Applications

Plate evaporator, or plate type evaporator is widely used in light industry, chemical industry, metallurgy,food, pharmaceutical, paper, environmental protection and other industries dueto their high efficiency and energy saving.

With high efficiency (the total transfer coefficient is 2-4 times of the tube evaporator), compact structure, convenient disassembly and cleaning, low liquid holding capacity, short time of materials at high temperature, etc., The plate evaporator is suitable for concentration of various materials., such as concentration in milk powder and condensed milk production, and concentration in juice, beverage, and pharmaceutical production.

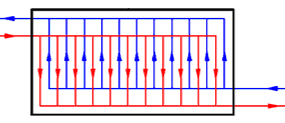

Design Principle

The plate evaporators are mainly based on the semi-welding technology of the rising-plate evaporator. The material evaporates in a channelwith a seal, while the steam heating medium condenses in the welded channels.The solution is injected from the bottom of the plate. The product flows upward along the wall of the plate under the action of a large amount of instantaneous steam.

What are the advantages of plate evaporator?

Higher O.H.T.C than shell and tube type evaporator, less heat transfer area

Better fouling resistance, low retention for better production quality

Easy for maintenance and expansion

Structure

Gasketed, hang-on frame design, flow section and flow path with rising plate, non-glued gasket sealing

Standard Materials

Plate AISI304,316L

Gasket NBR, EPDM, FKM

Plate Condenser

Recommended Applications

The plate condenser is primarily used in conjunction with a plateevaporator as a condensation of steam in an evaporation or distillation system.For example, the condensation of steam in the syrup 3-effect evaporationsystem, the condensation of steam in the juice 3-effect evaporation system, andthe condensation of steam in the multi-effect evaporation system of the ethanolconcentration in the ethanol industry, and the like. The plate condenser isused in more and more condensation occasions due to its high heat exchangeeffect, low input cost and convenient maintenance operation.

What are the advantages of plate condenser?

Porthole configuration design specially for maximizing heat transfer processing

Different channel gap sizes of two side media for minimizing fouling

Compact welded structure for lowering equipment cost

Design Principle

A plate condenser is a condenser developed for condensing steam based on an evaporation or distillation system under vacuum conditions. The plate condenser based on the semi-welding technique consists of special plate pack and gaskets. The cooling medium is warmed up in a channel with a gasket, and the steam is condensed in the weld channel. The steam has a large inlet and a small condensate outlet.

In order to achieve the best condensation effect, our wrench condenser’s plate channel is designed as a wide channel and a narrow channel, with a large channel on the steam side, so that the pressure drop on the steam side becomes very low, and the cooling medium The side has a narrower passage, but still maintains a certain flow rate to achieve turbulence. Therefore, such design makes it with higher heat exchange efficiency and lower fouling coefficient.

|

|